Chemicals

Chemicals are an integral part of modern life. Nagase offers a variety of intermediates and raw materials for chemical applications, with a portfolio that includes adhesives materials, such as aliphatic epoxies, materials for silicones and silanes, materials for textiles, and materials for CMP slurries.

We leverage the strength of our group companies, such as Nagase ChemteX, to provide multifaceted solutions. Partner with Nagase to innovate your brand for success.

Chemicals are an integral part of modern life. Nagase offers a variety of intermediates and raw materials for chemical applications, with a portfolio that includes adhesives materials, such as aliphatic epoxies, materials for silicones and silanes, materials for textiles, and materials for CMP slurries.

We leverage the strength of our group companies, such as Nagase ChemteX, to provide multifaceted solutions. Partner with Nagase to innovate your brand for success. Adhesives Materials

PAGS for cationic-UV curing of epoxies.

Mono- and multi-functional cycloaliphatic epoxies. Grades include low viscosity, good transparency, high heat resistance, high Tg, and good electrical properties. Non-yellowing with high flexibility and toughness. Suitable for thermal cure or UV cure (cationic).

Mono- and multi-functional aliphatic epoxy crosslinkers, reactive diluents, and modifiers. Grades include high functionality, varying degrees of water solubility, low chlorine content, hydroxyl functionality, and bio-based content. Low viscosity and non yellowing. Provides good adhesion to metal and nylon substrates.

Di-functional hydrogenated bisphenol A epoxy resin that provides excellent resistance to UV degradation. It is a highlighted grade in the DENACOL™ series of aliphatic epoxies.

Hydroxy-functional epoxy acrylates and methacrylates for UV/EB-curable ink, coating, and adhesive applications.

Reactive monomers effective in cationic UV-curing for reducing viscosity and increasing the cure speed of glycidyl ethers.

Increase the flexibility and impart toughness and impact resistance to thermosetting systems such as epoxy resins and unsaturated polyesters. Also used in temporary bonding applications.

Low Tg functionalized aliphatic acrylic esters. Low impurities, low residual monomer content, high molecular weight with narrow weight distribution. Three possible functional groups (COOH, OH, epoxy). Provides flexibililty, tack, cohesion, and peel strength.

Formulators can use it to deliver high-performance coatings that fulfill customer needs while imparting additional processing and end-use benefits. Denacol EX-622 can be used both in traditional epoxy systems and non-isocyanate (NISO) systems. Standard epoxy curatives such as amines can be used with Denacol EX-622 for traditional epoxy systems. For NISO systems, Denacol EX-622 can

EPOLEAD PB3600 is a premium resin modifier that imparts flexibility and improves impact resistance characteristics in cured products without negatively impacting adhesiveness when formulated with polyamine and/or anhydride curing agents. Additional benefits include: Lower epoxy-equivalent weight compared to conventional epoxidized polybutadienes Contains both epoxy groups and vinyl groups in the molecule, with terminal hydroxyl groups

Chemical-Mechanical Planarization (CMP) Slurry Materials

Amino acid that can be used metal complexing and finishing. This can be used for CMP slurry applicaitons

Raw Materials for Silicones and Silanes

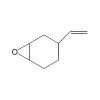

Contains two reactive groups, an epoxy and an allyl group, and can be used as a cross-linking agent, in surface treatment applications, for elastomers, fiber treatment, adhesives, paint and reactive monomers.

Cycloaliphatic epoxy with epoxy and vinyl group for use in various applications, such as coupling agent and UV-cure type paper release applications.