Quick Links

Polytetrafluoroethylene (PTFE)

(click to enlarge)

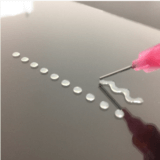

PTFE (Polytetrafluoroethylene) powder is used for its anti-scratch property for coatings and inks. Sintered PTFE powder provides improved durability and improved scratch resistance. Smaller particle sizes can be used to provide gloss.

Key Benefits

- Excellent scratch resistance for long time by sintered PTFE

- Keep Low viscosity by sintered PTFE

- Easy to disperse into UV coatings

- Choice of glossy or matte

Applications

- (UV curable) coatings that require anti-scratch effect. Used for mobile phones, digital cameras, PC and other electrical household appliances.

- (UV curable) inks that require anti-scratch effect, lithography (off-set) inks and screen-printing inks.

- Can and coil coatings

Additional Information

| Grade | KTL-2N | KTL-4N | KTL-8N |

|---|---|---|---|

| Appearance | White Powder No contamination |

White Powder No contamination |

White Powder No contamination |

| Max Particle Size (μm) |

7.78 or less | 11.00 or less | 15.56 or less |

| Dp50 (μm) | 3.00±1.00 | 3.00±1.00 | 5.00 or less |

| Apparent density (g/ml) | 0.50±0.10 | 0.55±0.10 | 0.55±0.10 |

| Volatile (wt%) | 0.20 or less | 0.30 or less | 0.10 or less |

| Whiteness | 97.00 or more | 95.00 or more | 97.00 or more |

XNR5516Z(D)

XNR5516Z(D)