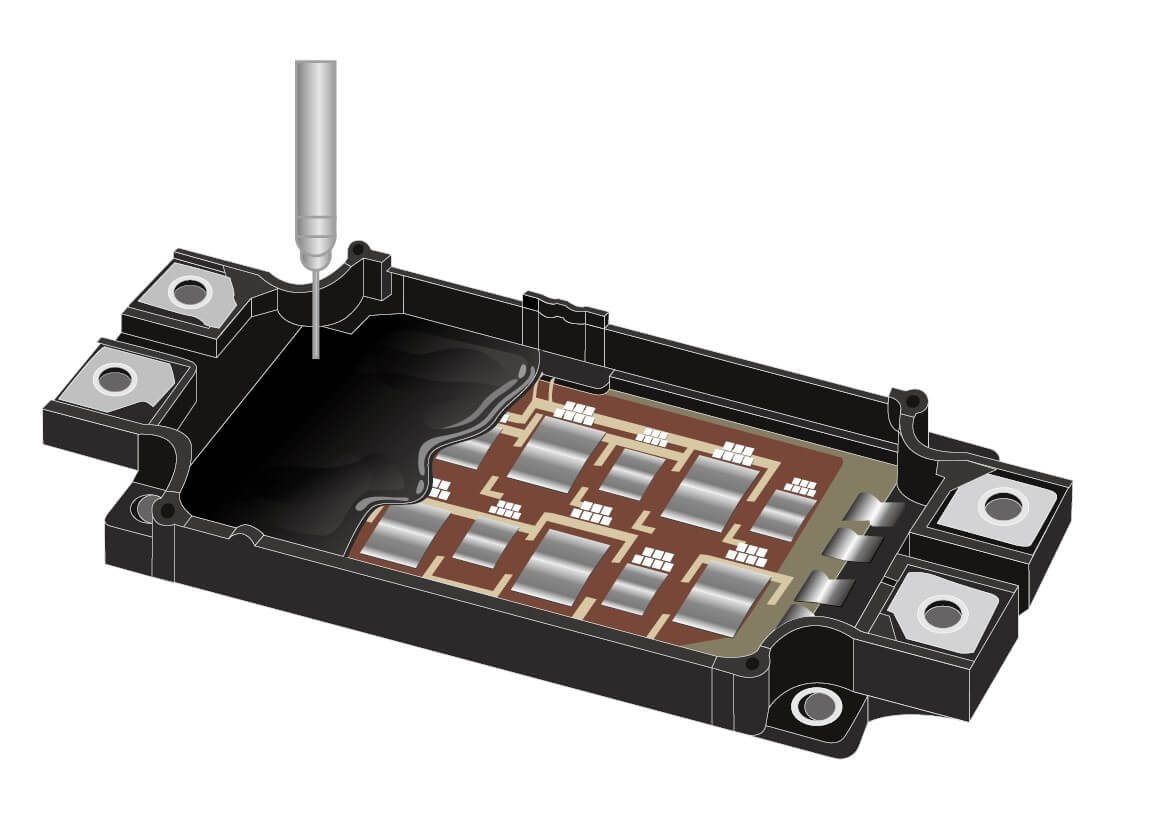

Potting

by: Nagase ChemteX

(click to enlarge)

With over 50+ years of automotive manufacturing innovation, we offer a variety of durable encapsulations for automotive electronic applications. Our encapsulations range from Potting, Underfill and Dam/Fill, and are specifically engineered to provide advanced resistance to thermal shock, vibrations, moisture, and corrosive agents. This allows for the highest-level of protection for the semiconductor chip, solder, wire bonding, and other components. Our materials are uniquely designed to be completely customizable based on any application needs. We are committed to partnering with manufacturers to create one-of-a-kind, customized solutions.

Product Features

- Epoxy potting material for power module, ECU, and traction motor

- 200°C Resistant

- Crack Resistant

- High Thermal Conductivity

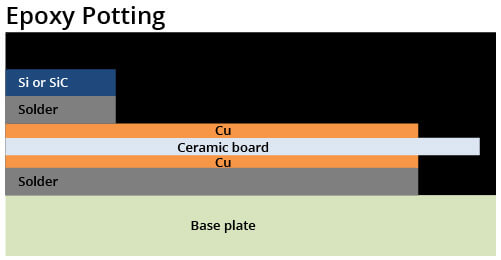

Benefit of Epoxy Potting — Solder/Wire Bonding Protection

CTE mismatch between Chip/Ceramic and Ceramic/Base Plate creates stress on solder or wire bonding during thermal cycle. The stress increases as junction temperature increases from 125°C to 175°C. Our Epoxy Potting materials provide high crack resistance at elevated temperatures and, consequently, extend part life.

Product Information

Products |

Resin |

629-3A |

XNR5025 |

R-1981-1GS |

R-4900-2GS |

XNR4175 |

|

Hardener |

629-3B |

XNH5021 |

H-1980 |

H-1980 |

XNH4175 |

||

Features |

Standard Low Viscosity |

Flame retardants Low CTE |

High Tg Low modulus High adhesion |

High Tg Low CTE High adhesion |

High thermal conductivity |

||

Mixing Ratio (R/H) |

wt% |

100 : 100 |

100 : 100 |

100 : 125 |

100 : 80 |

100 : 60 |

|

Cure Condition (Standard Condition) |

150℃/1hr |

100℃/1hr + 150℃/3hr |

90℃/1.5hr + 180℃/2hr |

90℃/1.5hr + 180℃/2hr |

100C/1hr + 150C/3hr |

||

Resin Viscosity (25℃) |

25℃ |

Pa・s |

11 |

100 |

230 |

400 |

364 |

Hardener Viscosity (25℃) |

25℃ |

Pa・s |

0.9 |

6 |

21 |

21 |

13 |

Mixture Viscosity |

60℃ |

Pa・s |

0.8 |

3 |

6 |

10 |

4.8 |

Gelation Time |

100℃ |

min |

- |

25 |

33 (90℃) |

33 (90℃) |

12 |

Tg (DSC) |

℃ |

158 |

167 |

201 |

205 |

163C |

|

Flexural Modulus (DMA) |

25℃ |

GPa |

13 |

17 |

11 |

18 |

16 |

Die shear strength (Cu) |

25℃ |

N/mm2 |

- |

12 |

19 |

19 |

- |

CTE (TMA) |

<Tg |

10-6K-1 |

23 |

15 |

17 |

12 |

14 |

Other properties |

US and China production |

3.2 mm V-0 |

New(Development) 6.4mm V-0 (Internal test) |

New(Development) 6.4mm V-0 (Internal test) |

Thermal conductivity 1.0W/m・K |

||

Synthetic Leather

Synthetic Leather