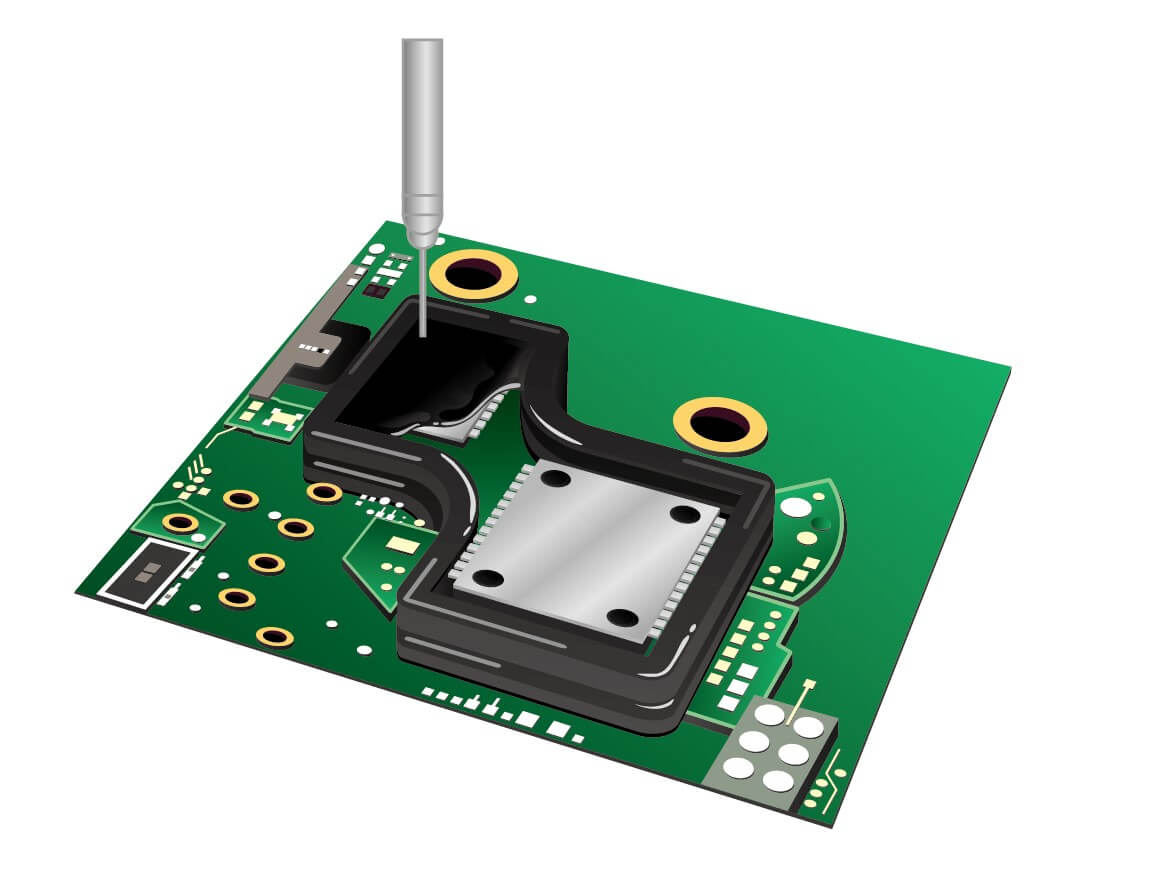

Dam/Fill

by: Nagase ChemteX

(click to enlarge)

With over 50+ years of automotive manufacturing innovation, we offer a variety of durable encapsulations for automotive electronic applications. Our encapsulations range from Potting, Underfill and Dam/Fill, and are specifically engineered to provide advanced resistance to thermal shock, vibrations, moisture, and corrosive agents. This allows for the highest-level of protection for the semiconductor chip, solder, wire bonding, and other components. Our materials are uniquely designed to be completely customizable based on any application needs. We are committed to partnering with manufacturers to create one-of-a-kind, customized solutions.

Product Features

- Partially potting solution for housing-less modules

- Dam and Fill can be cured at the same time

- Quick Cure

Product Information

Resin |

XNR5021 |

XNR5021 |

T-933/R-102 |

||

Hardener |

XNH5021 |

T700/H-3601 |

|||

Features |

Temp. |

Unit |

Fill Two part |

Fill Two part |

DAM One part |

Mixing Ratio (R/H) |

- |

wt% |

100/85 |

100/85 |

- |

Cure Condition (Standard Condition) |

- |

- |

100℃/1h +150℃/3h |

150C/10min |

≧150℃/10min |

Resin Viscosity (25dC) |

25℃ |

Pa.s |

100 |

100 |

- |

Hardener Viscosity (25dC) |

25℃ |

Pa.s |

6 |

3 |

- |

Mixture Viscosity (25dC) |

25℃ |

Pa.s |

33 |

16 |

992 |

Mixture Viscosity (60dC) |

60℃ |

Pa.s |

4 |

2 |

- |

Gelation time |

100℃ |

min |

27 |

14 |

- |

Tg (DSC) |

- |

℃ |

167 |

168 |

151 |

CTE(<Tg) |

<Tg |

10-6K-1 |

15 |

(15) |

17 |

Storage condition |

0 ~ 40℃ |

0 ~ 40℃ |

< 5℃(Under evaluation) |

||

Synthetic Leather

Synthetic Leather