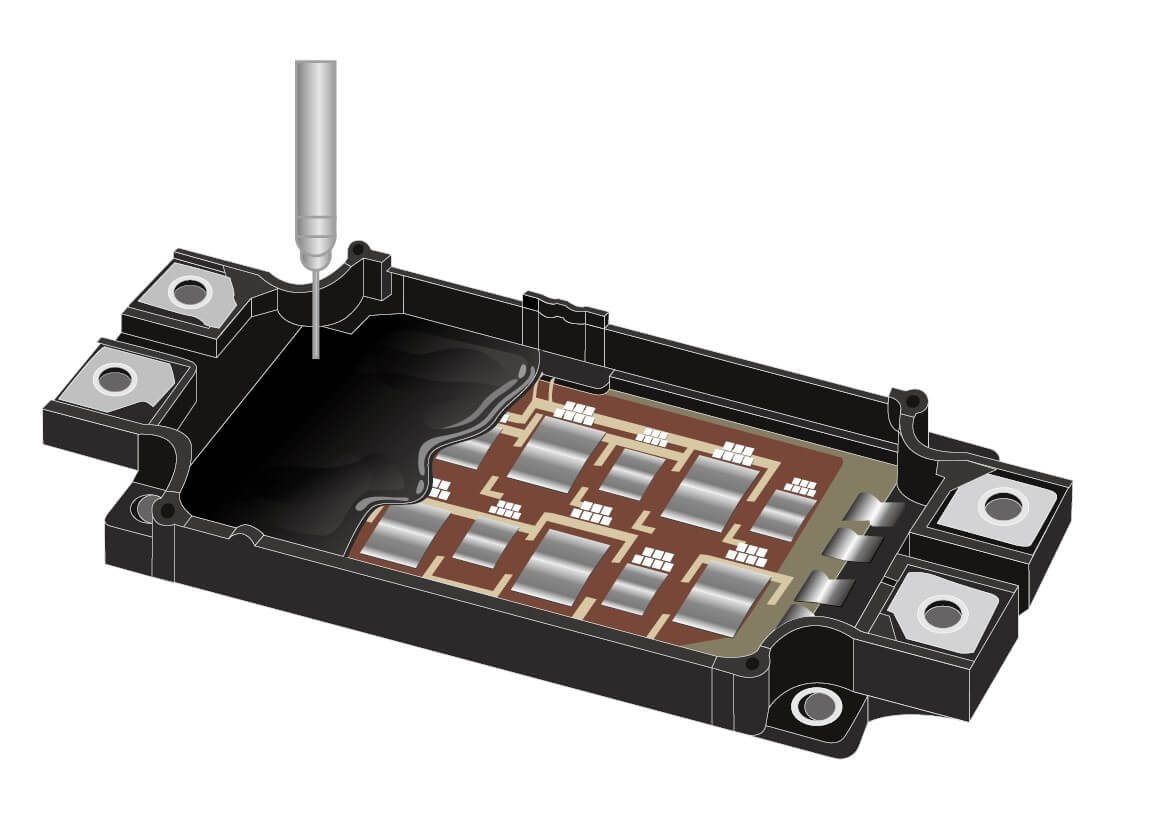

Potting

by: Nagase ChemteX

Product Features

- Epoxy potting material for power module, ECU, and traction motor

- 200°C Resistant

- Crack Resistant

- High Thermal Conductivity

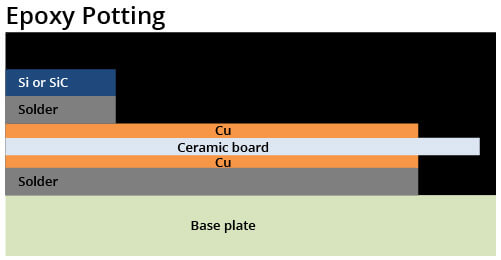

Benefit of Epoxy Potting — Solder/Wire Bonding Protection

CTE mismatch between Chip/Ceramic and Ceramic/Base Plate creates stress on solder or wire bonding during thermal cycle. The stress increases as junction temperature increases from 125°C to 175°C. Our Epoxy Potting materials provide high crack resistance at elevated temperatures and, consequently, extend part life.

Product Information

Products |

Resin |

629-3A |

XNR5025 |

R-1981-1GS |

R-4900-2GS |

XNR4175 |

|

Hardener |

629-3B |

XNH5021 |

H-1980 |

H-1980 |

XNH4175 |

||

Features |

Standard Low Viscosity |

Flame retardants Low CTE |

High Tg Low modulus High adhesion |

High Tg Low CTE High adhesion |

High thermal conductivity |

||

Mixing Ratio (R/H) |

wt% |

100 : 100 |

100 : 100 |

100 : 125 |

100 : 80 |

100 : 60 |

|

Cure Condition (Standard Condition) |

150℃/1hr |

100℃/1hr + 150℃/3hr |

90℃/1.5hr + 180℃/2hr |

90℃/1.5hr + 180℃/2hr |

100C/1hr + 150C/3hr |

||

Resin Viscosity (25℃) |

25℃ |

Pa・s |

11 |

100 |

230 |

400 |

364 |

Hardener Viscosity (25℃) |

25℃ |

Pa・s |

0.9 |

6 |

21 |

21 |

13 |

Mixture Viscosity |

60℃ |

Pa・s |

0.8 |

3 |

6 |

10 |

4.8 |

Gelation Time |

100℃ |

min |

- |

25 |

33 (90℃) |

33 (90℃) |

12 |

Tg (DSC) |

℃ |

158 |

167 |

201 |

205 |

163C |

|

Flexural Modulus (DMA) |

25℃ |

GPa |

13 |

17 |

11 |

18 |

16 |

Die shear strength (Cu) |

25℃ |

N/mm2 |

- |

12 |

19 |

19 |

- |

CTE (TMA) |

<Tg |

10-6K-1 |

23 |

15 |

17 |

12 |

14 |

Other properties |

US and China production |

3.2 mm V-0 |

New(Development) 6.4mm V-0 (Internal test) |

New(Development) 6.4mm V-0 (Internal test) |

Thermal conductivity 1.0W/m・K |

||

Synthetic Leather

Synthetic Leather